Product Performance

DZP series frequency conversion vibrating pile hammer is a new product independently developed by Shanghai Zhenzhong Construction Machinery Technology Co., Ltd. with high performance, easy operation and national conditions. Compared with traditional vibratory pile hammers, DZP series frequency conversion vibratory pile hammers show obvious advantages, mainly including:

◆Low starting energy consumptionUse frequency converter to start with variable frequency to reduce starting energy consumption. The power of the configured power supply is generally within 2 times of the power of the vibrating pile hammer motor, which meets the requirements of energy saving and emission reduction | ◆Adjust different vibration frequenciesFrequency conversion by frequency converter can adjust different vibration frequencies to meet the requirements of selecting different frequencies for different geological conditions to achieve construction frequency |

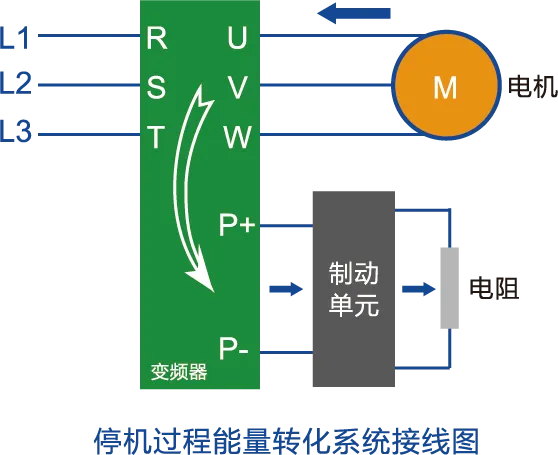

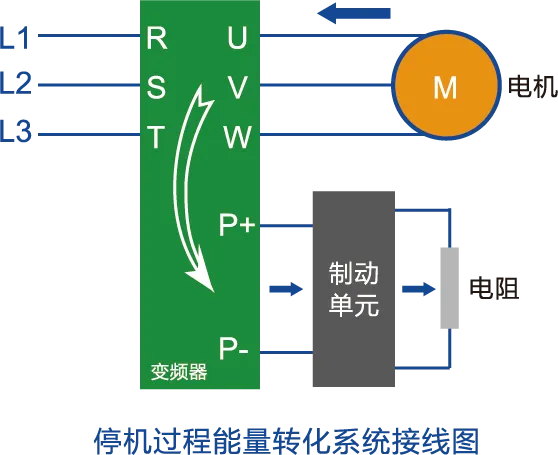

◆Fast and smooth shutdownThrough the energy conversion system when shutting down, the rotational kinetic energy is quickly converted into electric energy, and then the electric energy is converted into heat energy and released, so that the shutdown process is fast and stable, avoiding the generation of resonance, and preventing the strong noise generated by resonance and the impact on the vibrating pile Occurrence of damage to the hammer itself and related equipment | ◆High efficiency, energy saving, safety and environmental protectionThe configured motor is a vibration-resistant frequency conversion motor with independent intellectual property rights, and the motor has a longer service life. In short, compared with the traditional vibrating pile hammer, this machine not only has a scientific and reasonable overall structure, but also obviously has the characteristics of energy saving, which is a major breakthrough in the existing vibrating pile hammer technology. |

The principle of frequency conversion vibrating pile hammer without resonance shutdownThe principle of non-resonance shutdown of frequency conversion vibrating pile hammer is: when starting, the output voltage of the frequency converter drives the motor, and the vibrating pile hammer starts to rotate. As the frequency of the frequency converter increases, the speed of the vibrating pile hammer becomes faster and faster. The positive and negative terminals of the busbar are connected to the braking unit, and the inverter does not act because the voltage at the positive and negative terminals of the DC busbar does not reach the set voltage for triggering the braking unit. When stopping or decelerating, at the moment when the inverter frequency decreases, the synchronous speed of the motor will drop accordingly, and due to the mechanical inertia, the arrow is the current direction of the motor when the motor is generating power) The rotor speed of the motor does not change, when the synchronous speed When it is less than the rotor speed, the phase of the rotor current changes almost 180°, and the motor changes from a motoring state to a generating state. At the same time, the torque on the motor shaft becomes the braking torque, so that the speed of the motor drops rapidly, and the motor is in a regenerative braking state. The electric energy regenerated by the motor is rectified by the diodes in the inverter and then fed back to the DC bus circuit. Since the electric energy of the DC circuit cannot be fed back to the power grid through the rectifier bridge, it only depends on the absorption of the inverter itself. Although other parts can consume part of the electric energy, the capacitor still has a short-term charge accumulation, forming a "pump voltage" to make the DC bus voltage raised. At this time, the braking unit starts to work, conducts the regenerative electric energy generated by the load-driven motor and consumes it on the braking resistor through heat generation, so as to improve the braking capacity of the inverter and ensure that the motor can stop quickly within the set time . The rapid stop of the motor can effectively avoid the resonance of the mechanical end of the vibrating pile hammer, and achieve the function of protecting the frequency converter, motor and related mechanical parts and mechanical equipment. |

|

Product Parameters

Project | Unit | DZP45 | DZP60 | DZP90 | DZP90KS | DZP120 | DZP120KS | DZP150 |

Motor power | kW | 45 | 60 | 90 | 45*2 | 120 | 60*2 | 150 |

Static eccentric moment | kg*m | 25 | 37 | 47 | 52 | 71 | 71 | 77 | 97 |

Maximum vibration frequency | r/min | 1150 | 1100 | 1050 | 1000 | 1000 | 1000 | 1100 | 970 |

Exciting force | t | 37 | 50 | 58 | 58 | 80 | 80 | 104 | 102 |

No-load amplitude | mm | 8.9 | 9.9 | 10.3 | 9.7 | 13.6 | 8.3 | 11.4 | 14 |

No-load acceleration | g | 13.1 | 13.4 | 12.8 | 10.8 | 15.4 | 9.3 | 15.4 | 14.8 |

Maximum allowable pile pulling force | t | 20 | 20 | 25 | 25 | 40 | 40 | 40 |

Vibrating mass | Without clamp | kg | 2800 | 3744 | 4560 | 5370 | 5195 | 8610 | 6750 | 6900 |

Total mass | kg | 3820 | 5109 | 6160 | 7190 | 7162 | 11780 | 8650 | 8800 |

Long | mm | 1190 | 1370 | 1523 | 2390 | 1720 | 3120 | 1975 |

Width | mm | 1100 | 1250 | 1250 | 1420 | 1310 | 1690 | 1425 |

High | mm | 2340 | 2395 | 2552 | 2060 | 2640 | 2540 | 3061 |

Project | Unit | DZP150KS | DZP180 | DZP180KS | DZP200 | DZP240 | DZP300 |

Motor power | kW | 75*2 | 180 | 90*2 | 200 | 240 | 300 |

Static eccentric moment | kg*m | 150 | 150 | 200 | 150 | 250 | 220 | 300 | 300 | 400 |

Maximum vibration frequency | r/min | 760 | 860 | 750 | 860 | 680 | 810 | 660 | 760 | 620 |

Exciting force | t | 97 | 124 | 126 | 124 | 130 | 161 | 146 | 203 | 172 |

No-load amplitude | mm | 15.5 | 14 | 18 | 10.7 | 21.2 | 15.7 | 21 | 18.1 | 23.7 |

No-load acceleration | g | 10 | 11.6 | 11.3 | 8.9 | 11 | 11.5 | 10.2 | 11.7 | 10.2 |

Maximum allowable pile pulling force | t | 40 | 60 | 60 | 60 | 90 | 90 |

Vibrating mass | Without clamp | kg | 9700 | 10700 | 11100 | 13990 | 11800 | 14000 | 14300 | 16600 | 16900 |

Total mass | kg | 12870 | 13900 | 14300 | 18250 | 15000 | 19300 | 19600 | 23300 | 23600 |

Long | mm | 3140 | 2450 | 3550 | 2450 | 2500 | 2500 |

Width | mm | 1690 | 1500 | 2000 | 1500 | 1830 | 1890 |

High | mm | 2550 | 3440 | 2980 | 3440 | 3720 | 4350 |

Project | Unit | DZP360KS | DZP400 | DZP500 | DZP600 |

Motor power | kW | 180*2 | 400 | 500 | 600 |

Static eccentric moment | kg*m | 350 | 300 | 400 | 500 | 480 | 580 | 580 | 680 |

Maximum vibration frequency | r/min | 680 | 820 | 700 | 580 | 750 | 580 | 680 | 580 |

Exciting force | t | 180 | 226 | 219 | 188 | 302 | 218 | 300 | 256 |

No-load amplitude | mm | 24.1 | 22 | 16.8 | 16.8 | 17 | 20.5 | 20.1 | 21.2 |

No-load acceleration | g | 12.4 | 12.4 | 12.6 | 12.6 | 10.7 | 7.7 | 10.5 | 8 |

Maximum allowable pile pulling force | t | 72 | 90 | 120 | 120 | 120 | 180 |

Vibrating mass | Without clamp | kg | 14500 | 18200 | 17900 | 26400 | 28100 | 28300 | 28500 | 32000 |

Total mass | kg | 19000 | 24900 | 24600 | 33900 | 35700 | 35900 | 36200 | 39800 |

Long | mm | 2970 | 2250 | 2580 | 2580 | 2600 | 2780 |

Width | mm | 1790 | 1940 | 2240 | 2240 | 2240 | 2260 |

High | mm | 2810 | 4450 | 5185 | 5185 | 5200 | 5800 |

Application Scope

Vibration-sinking prefabricated engineering piles (steel pipe piles, concrete piles) and cast-in-place piles can also be used for sinking and pulling temporary support (steel pipe, steel plate) piles, as well as foundation improvement and other engineering construction.