With the increasing use of PHC concrete prefabricated pipe piles in large-scale engineering foundation construction, especially in soil layers above medium coarse sand, the existing construction methods such as static pressure machine pressing method, hydraulic hammer driving method, drilling machine drilling and implantation method, and Japanese medium excavation method are difficult to construct large-diameter PHC piles, with high cost and low efficiency.

The method of sinking large-diameter PHC pipe piles through internal excavation vibration is aimed at the hollow characteristics of large-diameter pipe piles, combined with the construction methods of vibration pile hammers and drilling machines, fully utilizing their respective advantages. It not only uses a drilling rig to extract soil from the pile and reduce pile end resistance, but also uses vibration to reduce pile side resistance to achieve the purpose of pile sinking. The construction method and process:

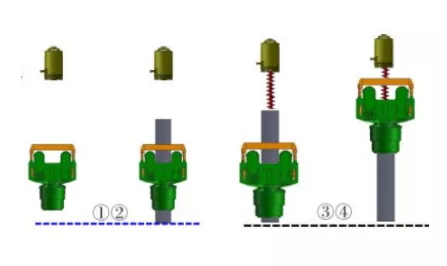

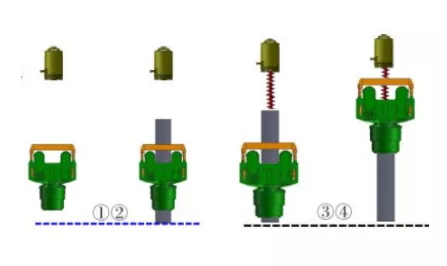

① Move the drilling rig up and the middle hole vibration hammer down, so that the distance between the drilling rig and the middle hole vibration hammer is longer than that of the pile.

② Use a crane or a pile frame auxiliary crane to feed the pipe pile into the middle hole vibration hammer and fixture from top to bottom.

③ Feed the drill rod into the pipe pile from top to bottom using a crane or a pile frame auxiliary crane; Move the drilling rig downwards to connect the drilling rig joint with the drill pipe joint.

④ Move up the middle hole vibration hammer and clamp the upper part of the pipe pile with the fixture; Align the pile position and adjust the verticality.

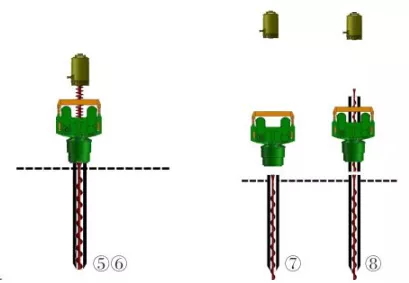

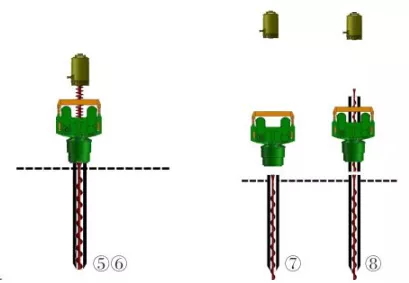

⑤ Turn on the vibration hammer, sink the pipe pile, and then turn on the drilling rig to extract and discharge soil from the pile pipe; Alternatively, the drilling rig can be turned on first to collect and discharge soil, and then the vibratory hammer can be used to lower the sinking pile; Alternatively, the drilling rig rotates to extract and discharge soil, and the vibrating hammer vibrates the sinking tube alternately.

⑥ The lower end of the pipe pile sinks to a certain elevation and stops the vibration of the middle hole vibration hammer; Continue to rotate the drilling rig and discharge soil until the drill bit penetrates the bottom of the inner hole of the pipe pile, and stop the rotation of the drilling rig.

⑦ Remove the connection between the drilling rig and the drill rod, and loosen the fixture. Move the drilling rig up and slightly move the middle hole vibration hammer up, so that the distance between the drilling rig and the vibration hammer is greater than the length of the pipe pile.

⑧ Feed the second section of the pipe pile into the middle hole vibration hammer and fixture from top to bottom, and clamp the pipe pile tightly with the fixture; Move the middle hole vibration hammer slightly upwards, and use a crane or pile frame auxiliary crane to feed the drill rod into the pipe pile from top to bottom.

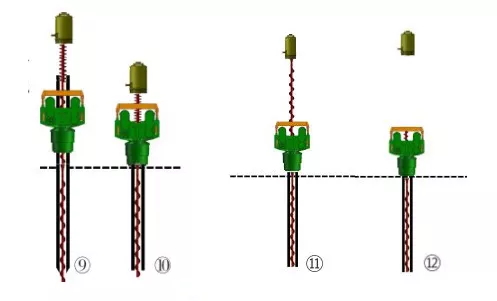

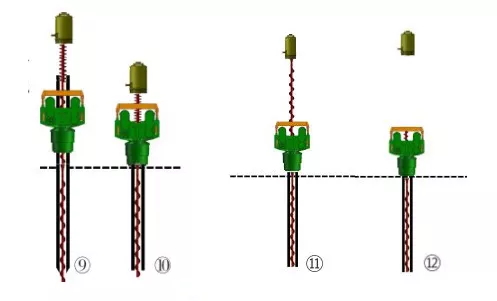

⑨ First, connect the drill rod in the second section of the pipe pile to the drill rod in the first section of the pipe pile, and then move down to connect the second section of the pipe pile to the first section of the pipe pile (using mechanical coupling buckles or welding connections); Lower the drilling rig and connect it to the second section of the drill pipe; Move up the middle hole vibration hammer and clamp the upper part of the pipe pile with the fixture.

⑩ Turn on the vibration hammer, sink the pipe pile, and then turn on the drilling rig to extract and discharge soil from the pile pipe; You can also start the drilling rig to collect and discharge soil first, and then start the vibration hammer to lower the sinking pile; Alternatively, the drilling rig rotates to extract and discharge soil, and the vibrating hammer vibrates the sinking tube alternately.

⑪ Stop the vibration hammer of the middle hole when the pipe pile sinks to the new elevation; Continue to move the drilling rig upwards while rotating to discharge soil, until the lower end joint of the newly connected drill rod comes out from the upper mouth of the vibrating hammer in the middle hole, and the drilling rig stops rotating; Use a concave plate to fix the upper end of the first drill rod in the pile pipe at the upper opening of the hole in the vibrating hammer.

⑫ Use a crane or pile frame auxiliary suspension rope to lift the second section of drill pipe that was originally connected, remove the connection between the drill pipe and the drilling rig and the first section of drill pipe, and lift the drill pipe away.

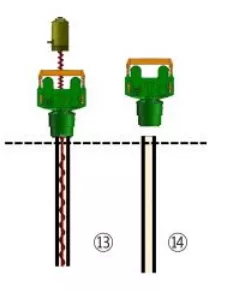

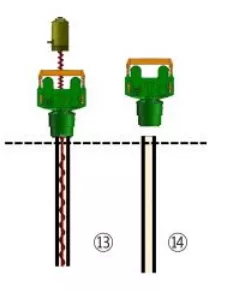

⑬ Move the drilling rig downwards to connect the drilling rig joint with the joint on the first section of the drill rod; Rotate the drilling rig while moving it up to discharge soil, until all the drill rods come out of the pile pipe; Use a crane or pile frame auxiliary suspension rope to lift the first section of drill pipe, remove the connection between the drill pipe and the drilling rig, and lift the drill pipe away.

⑭ Release the fixture, slightly move up the middle hole vibration hammer, and complete the vibration settlement of a total of 2 sections of pipe piles. If adding 3 or 4 sections of pipe piles, repeat steps ⑦ - ⑭.

The characteristics of this construction method are as follows:

1. It can be applied to any soil layer, and can be successfully completed in geological conditions such as flowing sand, silt, sand and gravel, prone to collapse holes, and underground confined water.

2. No "resonance" hazard, simultaneous wall protection and soil excavation, high pile forming efficiency.

3. The drilling rig only takes soil from the inner hole of the pipe pile, which belongs to partial soil sampling. It can ensure sufficient lateral friction resistance while reducing the adverse effects caused by full soil compaction.

4. No need for mud or other materials, construction is both civilized and clean, and not affected by weather conditions.