Basic principles

Cleverly utilizing the variation law of low soil resistance when vibrating the sinking double tube and high soil resistance when statically pulling out the inner tube, the vibrating hammer is equipped with the functions of soil extraction and hole formation.

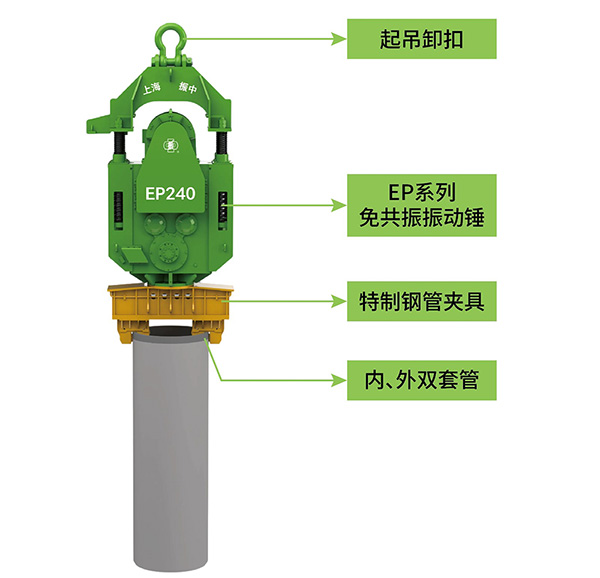

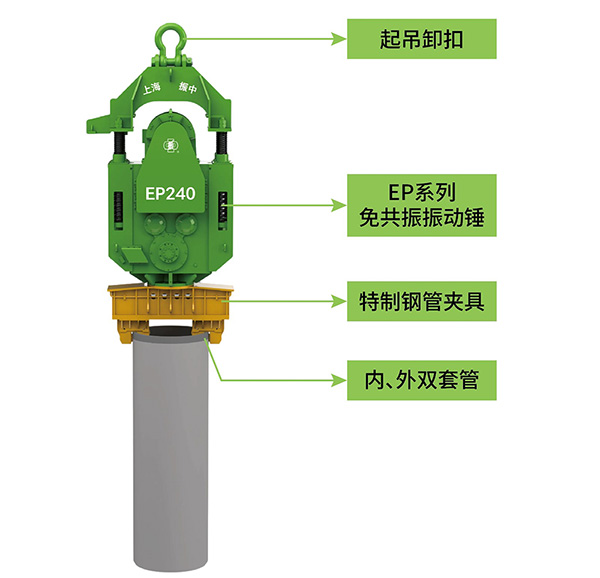

construction equipment

● EP series resonance free vibration hammer

-During the construction process, the eccentric moment should be reduced to 50% to make the soil at the end more compact and avoid soil falling off during pipe lifting;

-Vibration induced soil removal in the air must use resonance free starting and stopping methods to avoid damage to lifting equipment;

●Active steel pipe fixture

-Specially designed steel pipe fixtures that can clamp both inner and outer double pipes, as well as single inner pipes;

●Internal and external steel pipes

-The outer pipe is used for separating soil and protecting walls;

-The inner pipe is used for soil extraction and discharge;

●Lifting equipment

-Construction can be carried out using crawler cranes, truck cranes, and ship cranes

construction equipment

Application and construction method extension

● Applied to soil sampling and pore forming

The project requires a hole diameter of 800mm and a depth of 40m. The geological soil properties include silt, sandy soil, and hard plastic cohesive soil at different depths. Use EP550 resonance free vibration pile hammer to directly vibrate and sink 40m double casing, and use the inner pipe as a soil sampler to take out 20 cubic meters of soil in one bucket, forming a hole position.

● Applied to pulling out old piles and breaking piles

The vibration hammer is commonly used for pulling out piles. But when it comes to pulling out the cast-in-place pile, especially if the pile is broken due to poor pouring quality, the vibrating hammer can only pull out the previous section.

By using the double casing soil extraction process, anything in the soil, including broken piles, can be completely removed.

●Suitable for the construction of cast-in-place piles

After completing step 4 of the double casing basic construction method, the outer pipe remains in its original pile position. The outer pipe can be used as a protective wall, a steel cage can be inserted into the outer pipe, and a certain amount of cement slurry can be poured in. Then, the vibration hammer can be turned on to pull out the outer pipe through vibration, and the original pile position forms a reinforced concrete cast-in-place pile. Alternatively, cement slurry can be directly poured into the outer pipe, leaving the outer pipe in the soil to form a steel reinforced concrete pile.

● Applied to prefabricated pile planting construction

After completing step 4 of the double casing basic construction method, the outer pipe remains in its original pile position. The outer pipe can be used as a protective wall, and a certain amount of cement slurry can be injected into the outer pipe. Then, the PHC pile can be inserted into the pile hole, and the vibration hammer can be turned on to pull out the outer pipe through vibration, completing the planting of PHC piles. Alternatively, first place the PHC pile into the hole, then inject a certain amount of cement slurry, remove the outer pipe, and complete the planting of the PHC pile.